SOP for sampling of Raw Materials

In pharmaceutical companies, every job is expected to be done according to a pre-approved SOP. Similarly, SOP for sampling of Raw Materials is assigned for the sampling of incoming raw materials in the company. SOP should contain all directions according to GMP guidelines. The SOP would have to extensively cover the operation and precautions related to contamination.

According to Canadian Health Authority, "Sampling plans and procedures must be statistically valid and based on scientifically sound sampling practices." For a large number of containers, the sampling plan based on (√n+1) can be followed.

1. Objective: To lay down a procedure for Sampling Raw Materials.

2. Scope: The procedure of this SOP shall be applicable to the Store Department of ABC Pharmaceuticals,

3. Responsibility: Store Incharge

4. Accountability: Q.A. Manager

5. Abbreviations :

S.O.P.: Standard Operating Procedure

QC: Quality Control

QA: Quality Assurance

The SOP of sampling of Raw Materials is not completed without the procedure of cleaning the sampling booth and operating of sampling booth laminar airflow because the raw material can not be dispensed or sampled in the open air in the room. If the Raw Material container is opened in the room atmosphere it can be contaminated with particles flowing into the raw material store. To avoid possible contamination we must use Sampling Booth Laminar Airflow.

Therefore, before knowing the SOP of sampling of Raw material we must follow the procedure for cleaning and operation of Raw Materials sampling booth Laminar Airflow.

ALSO READ: SOP for Control sample handling

6. Procedure for Cleaning & Operation of Raw Materials Sampling Booth Laminar Airflow.:

Switch off the UV light, Air of LAF.

Regularly clean the inside surface as well as the outside surface of LAF with a clean and dry synthetic cloth before the start and after completion of the Sampling operation.

- On week open the screws of the prefilter cabinet and disconnect the cabinet.

- Now remove the prefilters and clean using pressurized compressed air reversibly.

- Now rinse with the soap solution.

- Rinse thoroughly with raw mater.

- Finally, dry using pressurize compressed air.

- Affix cleaned and dried prefilter.

- Clean filter cabinet with soap solution and finally rinse with raw water.

- Dry with compressed air.

- Connect Cabinet.

Also Read: What is ALCOA+?

7.0 Operation of Sampling Booth Laminar Air Flow :

- Switch on UV light LAF prior to half hour of sampling operation.

- Ensure during UV expose any Raw Materials should not be in side the booth.

- Switch off UV light before start sampling operation.

- Ensure LAF air pressure is in between 2 to 15 mm during sampling operation.

- Ensure Exhaust pressure is in between 1 to 6 mm during sampling operation.

- Maintain sampling Booth pressure record.

8. Procedure for sampling of Raw Materials:

8.1 The received material is unloaded on the received bay & dedusting of the same is done.

8.2 Then the raw material. Containers or bags shifted to the under test area. The containers are kept on the PVC pellets.

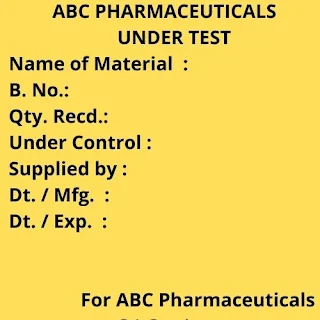

8.3 The under test labels are pasted on each container having the following information.

8.4 After that the information is sent to the Q.C. department in the following format.

8.5 As the information is given in triplicate, the Q.C. department copy. The triplicate copy is sent back to the store department.

8.6 The Q.C. a person will come to draw the sample along with the information slip & draw the sample in poly bags.

8.7 On the right side of each container, the sticker of the sample by & date will be posted.

8.8 Each container will be closed properly.

After testing, if the material is found OK in testing, the Q.C. person will paste the “Approved” Label on the under-test slip in such a way that under test should be masked completely.

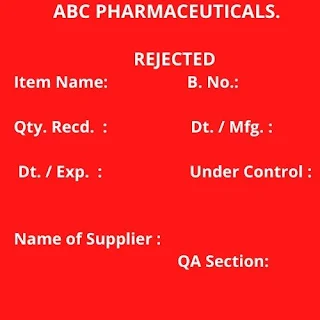

If the material is rejected the Q.C. person will paste a rejected” Label on the under-test slip. The report of approved or rejection will be given to the store in charge.

|

| rejected-slip-specimens |

References:

- Q7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients-FDA

- WHO guidelines for sampling of pharmaceutical products and related materials-WHO

- "Good Manufacturing Practices (GMP) Questions and Answers"-Canadian Health Authority.

Please not enter any spam link in the comment box.